Twin Shaft Mixer Disperser

Price 1.50000 INR/ Piece

Twin Shaft Mixer Disperser Specification

- Driven Type

- Electric

- Efficiency (%)

- Above 90%

- Installation Guideline

- Foundation Required, Electrical Setup Required

- Accessories

- Jacketed Vessel, Scraper Blade, Control Panel

- Production Capacity

- Customized

- Plastic Processed

- PVC, PET, PE, PP, HDPE, EVA

- Temperature Range

- 0°C to 120°C

- Frequency

- 50/60 Hz

- Usage & Applications

- Mixing, Blending, Dispersing Viscous Materials

- Source

- Manufacturer

- Motor Power

- 10 HP

- Type

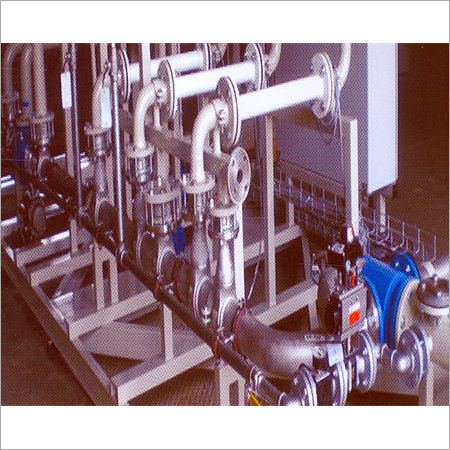

- Twin Shaft Mixer Disperser

- Material

- Stainless Steel

- Computerized

- No

- Control System

- PLC Based

- Drive Type

- Electrical Motor

- Dimension (L*W*H)

- 1800 x 1200 x 1400 mm

- Color

- Blue/Grey

- Surface Finish

- Polished

- Power Consumption

- Approx. 10 kW

- Machine Type

- Batch/Continuous

Twin Shaft Mixer Disperser Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Twin Shaft Mixer Disperser

Twin Shaft Mixer Disperser manufactured by S. F. Engineering Works is developed with the help of sound manufacturing unit and experienced personnel. An exclusive range of mixer dispenser is widely demanded in several industries for different applications such as plastic pastes, ointments, sealing compounds, paints and printing inks and construction materials. The machine offered by us in the market is well known for its features like sturdy construction, easy installation and long operational life.

Further Details:

- 1 number 15 / 7.5HP twin shaft mixer

- Disperser with hydraulic lifting arrangement which can mix materials of specific gravity ranging from 1 to 1.3.Premix Capacity 500Lt

- Working Principle:

- The dispersers are designed for processing highly viscous material containing high percentage of solids and which are to be evenly dispersed with small quantities of liquid, solid additives and fillers.

- The machine has a combination of two shafts rotating inside a vessel to achieve these results in short intervals

- A low speed centrally located butterfly blade agitators mixes and moves the material around the vessel and into the path of high speed shaft

- The shaft on entering the high speed zone the material is subjected to high shear turbulent forces

- This force ensures that the entire mass in the vessel is evenly dispersed and homogenously mixed

- By periodically varying the height and speed of the shafts and the level the quality of productivity can be increased to the desired levels

Application:

Mixing pastes, dispersing, emulsifying, breaking down agglomerates dissolving and homogenizing viscous materials, such as primers, creams photographic emulsions, adhesive, pigmented coating compounds and resin solutions, printing Inks, adhesives, etc.

Advantage:

- Outstanding dispersing performance and uniform fineness

- Vertical flow of the circulating materials effects rapid entry of fine powdery components

- Drastically reduces mixing time

- Minimum heating of the batch

- Low energy consumption

- Simple servicing and maintenance

- The central control panel provided with indicators for all functions

- Simplified operation and processing

Features:

- Low-speed butterfly agitator and high-speed disperser disc

- Frequency converter drive or hydrostatic drive

- Drive power ranges from 7.5 KW to 90 KW

- Batch sizes ranges from approx 10 to 2500 liters

Construction

Body: The frame is made from angles and house the body casting and guide pipe. The base frame is 12 mm thick made from MS plates and houses the entire power back. The top frame has the motor and the shaft assembly.

Agitator main shaft: Shaft is of 50 mm diameter made from SS – 304 MOC tapered to 40 mm diameter. It is supported by two ball bearings of size 6212.

Central Vessel Clamping: The new vessel-clamping device the disperser shaft always remains in the center, precise parallel guidance of the clamping jaws results from the purely vertical circular movement of the hydraulically operated gripper-type system.

Drive: The shaft is powered by 15 HP 1440 RPM. 3 phase cage induction and NON-FLP motor though V grooves pulley and belts. The shaft speed can be varied between 0 to 1440/3000 RPM through an A\C frequency drive unit. The low speed shaft is powered by a 7.5 HP 1440 RPM motor coupled with shaft mounted reduction gear box having final 75 RPM.

Speed Control: Continuous speed adjustment from 0 to 1 to the maximal stirring shaft speed is realized as standard feature by a maintenance free frequency inverter control. The maximum speed desired for a dispersing process is selected earlier by a rotary type plus/minus switch. The disperser is constantly operated with minimum power consumption without exceeding the pre-selected limit speed.

Optional:

Vacuum arrangement

Heating and cooling arrangement

Automatic lifting and lowering of the mixing tools during the mixing process is provided and also under vacuum programmable logic control system

Explosion proof construction

Mixing tubs can be heated and cooled

Manufacture and Supplying

One Stainless Steel Tank of 500 liters capacity (working 400 liters)

Shell: shell is 750mm diameter X 1000 mm height made from 5mm thick SS plates

Bottom: The bottom is tapered and made from 6mm thick SS plates

Jacket: The jacket is 6mm thick and made from MS plates and covers the working volume of the tank

Wheels: Four PP castor wheels

Versatile Processing in Industrial Applications

Suitable for a variety of plastic materials, the Twin Shaft Mixer Disperser excels in mixing and dispersing viscous compounds within the plastic, chemical, and related industries. Its adaptable production modes accommodate both batch and continuous processes, making it invaluable for manufacturers seeking flexibility in their operations.

Enhanced Control and Efficient Operation

With a PLC-based electrical control system and a 10 HP electric motor, this mixer achieves above 90% efficiency while consuming approximately 10 kW. The systems precision control panel allows for straightforward adjustments, while the robust electric drive ensures continuous, reliable performance.

Customizable and Built to Last

The mixers stainless steel construction, polished finish, and included accessories like a jacketed vessel and scraper blade, make it durable and easy to clean. The dimension (1800 x 1200 x 1400 mm) enables integration into various production setups, with foundation and electrical setup guidelines provided for efficient installation.

FAQs of Twin Shaft Mixer Disperser:

Q: How is the Twin Shaft Mixer Disperser installed and what setup is required?

A: Installation of the Twin Shaft Mixer Disperser requires a stable foundation and appropriate electrical setup, in line with the provided guidelines. A dedicated space accommodating its dimensions (1800 x 1200 x 1400 mm) and electrical provisions for 10 kW power and a 10 HP motor are essential for optimal operation.Q: What materials can be processed with this mixer?

A: This mixer is engineered for processing a wide range of viscous materials, especially plastics such as PVC, PET, PE, PP, HDPE, and EVA, making it suitable for various industries including plastics, coatings, and chemicals.Q: When should a batch or continuous process be chosen for this mixer?

A: You should select the batch process for precise, small-to-medium volume runs, ensuring formulation accuracy. The continuous process is ideal when large-scale, uninterrupted production is required to achieve higher throughput.Q: Where can this equipment be effectively used?

A: The Twin Shaft Mixer Disperser is effective in industrial settings like polymer processing plants, chemical manufacturing units, and any facility requiring the blending and dispersing of viscous substances.Q: What is the benefit of the PLC-based control system in this mixer?

A: The PLC-based control system provides precise and automated control over mixing parameters, enhancing consistency, reducing manpower requirements, and improving production efficiency.Q: How does the jacketed vessel support the mixing process?

A: The jacketed vessel allows for precise temperature control within the 0C to 120C range, facilitating optimal mixing or dispersing conditions for sensitive or heat-reactive materials, resulting in better product quality.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Gravity Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Efficiency (%) : â¥98%

Surface Finish : Polished

Accessories : Standard change parts, Filling heads, Nozzle set

Automatic Batch Blender

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Motor Driven

Efficiency (%) : >98%

Surface Finish : Other, Polished / Painted

Accessories : Loading Hopper, Discharge Valve, Control Panel, Level Sensors

Semi Automatic Grease Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Driven Type : Electric

Efficiency (%) : 98%

Surface Finish : Polished

Accessories : Nozzle set, bottle support, power cable

In-Line Blending System

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Motor Driven

Efficiency (%) : 98%

Surface Finish : Other, Matt

Accessories : Calibration Kit, Spare Parts Set

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS