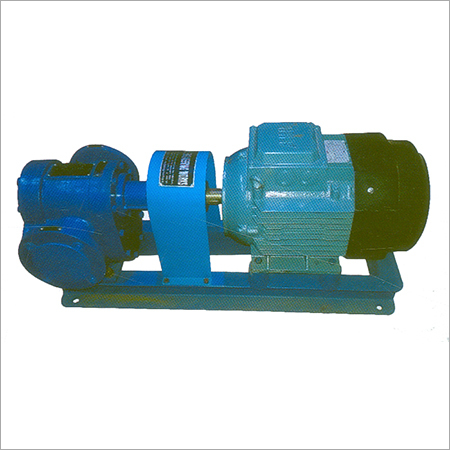

Feeding & Discharge Pump

Price 1.50000 INR/ Piece

Feeding & Discharge Pump Specification

- Driven Type

- Electric

- Automation Grade

- Semi-Automatic

- Accessories

- Standard Couplings, Suction & Delivery Hose

- Model No

- FDP-600

- Temperature Range

- Up to 120C

- Efficiency (%)

- >85%

- Installation Guideline

- Foundation Mount, Horizontal Installation, Connect to Electric Supply

- Usage & Applications

- Industrial fluid transfer, feed/discharge operations in process industries

- Speed

- 1440 RPM

- Frequency

- 50 Hz

- Motor Power

- 2 HP

- Production Capacity

- Varies as per application

- Type

- Feeding & Discharge Pump

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Electric

- Drive Type

- Electric Motor Driven

- Voltage

- 220-440 V

- Power

- 1 to 5 HP

- Weight (kg)

- 145 kg

- Dimension (L*W*H)

- 900 x 400 x 650 mm

- Color

- Metallic Grey

- Capacity

- Up to 600 LPH

- Features

- Corrosion Resistant, Robust Construction, Easy to Operate, Low Maintenance

- Machine Type

- Industrial Feeding and Discharge Pump

- Power Consumption

- 2.2 kW

- Surface Finish

- Polished

Feeding & Discharge Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Feeding & Discharge Pump

Reliable Performance for Diverse Industrial Needs

The FDP-600 Feeding & Discharge Pump stands out with its durable stainless steel construction and mechanical sealing, ensuring high resistance to corrosion and wear when handling water, chemicals, or slurries. Designed for both feeding and discharge roles, it delivers dependable operation with minimal maintenance, making it suitable for demanding industrial fluid transfer environments.

Efficient and User-Friendly Design

Engineered for efficiency and simplicity, the FDP-600 combines a high-performance 2 HP electric motor with self-lubricating bearings and semi-automatic controls. Its baseplate-mounted design streamlines installation, while air-cooled motor technology keeps noise levels below 70 dB, supporting a comfortable and productive workspace.

FAQs of Feeding & Discharge Pump:

Q: How is the FDP-600 Feeding & Discharge Pump installed?

A: The FDP-600 should be foundation-mounted horizontally using the baseplate provided. Connect the inlet and outlet using the supplied standard couplings and hose, then link the unit to the electric power supply (220440 V). Ensure all safety and operational checks are completed before starting the pump.Q: What types of fluids can this pump handle effectively?

A: This pump efficiently transfers a wide range of fluids, including water, chemicals, and slurries. The stainless steel impeller and corrosion-resistant construction make it suitable for industrial process applications involving aggressive or abrasive materials.Q: When is maintenance typically required for this pump?

A: Routine inspection and maintenance are minimal due to the self-lubricating bearings and robust design. Under standard usage, the pump requires only periodic checks of the seals and motor, contributing to a typical service life of 58 years.Q: Where is the FDP-600 most commonly used?

A: It is widely used in process industries for fluid feeding and discharge operations, such as in chemical plants, water treatment facilities, and other manufacturing settings requiring reliable and efficient industrial fluid transfer.Q: What are the key benefits of using this pump?

A: The primary benefits include corrosion resistance, robust stainless steel construction, low operational noise (<70 dB), high efficiency (>85%), easy operation, and low ongoing maintenance. These features ensure reliable long-term performance in demanding industrial environments.Q: How does the semi-automatic control system improve usage?

A: The semi-automatic controls allow operators to manage pump operations with ease, streamlining fluid transfer tasks and reducing the potential for operator error, while still providing flexibility for manual adjustments when needed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Semi Automatic Grease Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Frequency : 50 Hz

Usage & Applications : Suitable for bottle, jar, container grease filling

Material : Stainless Steel

Speed : Adjustable

Simultaneous Metering & Blending

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Usage & Applications : Plastic processing, compound mixing, extrusion lines

Material : Stainless Steel

Speed : Variable; 10100 rpm

Gravity Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Usage & Applications : Beverage, Edible Oil, Dairy, Chemicals, Pharmaceuticals, Cosmetics

Material : Stainless Steel

Speed : Up to 60 bpm

Automatic Batch Blender

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Usage & Applications : Plastic Compounding, Masterbatch Mixing, Recycling, Injection Molding, Extrusion

Material : Stainless Steel, Mild Steel

Speed : Variable (controlled via VFD)

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS