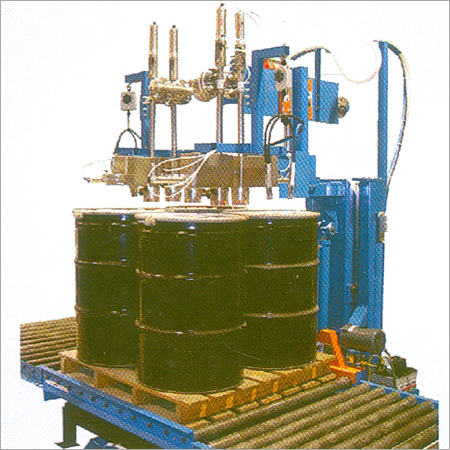

Dissolver Motorized Lifting

Dissolver Motorized Lifting Specification

- Motor Power

- 5 40 HP

- Source

- Manufacturer / Supplier

- Accessories

- Impeller Blade, Lifting Cylinder, Electrical Control Box, Safety Shields

- Temperature Range

- Ambient to 120C

- Frequency

- 50/60 Hz

- Usage & Applications

- Paint, Ink, Coating, Chemical, Pharma, Adhesive, Emulsion preparation

- Model No

- DML Series

- Production Capacity

- Up to 1000 liters/hr

- Efficiency (%)

- Up to 90%

- Speed

- Variable up to 1500 rpm

- Driven Type

- Motorized with Hydraulic Lifting

- Type

- Dissolver Motorized Lifting

- Material

- Mild Steel / Stainless Steel (as per client requirement)

- Control System

- Digital Control Panel

- Drive Type

- Electric Motor

- Power

- 5 HP 40 HP (Varies as per capacity)

- Weight (kg)

- 500 1500 kg

- Dimension (L*W*H)

- Variable (as per model and capacity)

- Color

- Industrial Blue/Grey (Customizable)

- Capacity

- 50 1000 liters (batch size)

- Features

- Motorized Hydraulic Lifting, Easy Cleaning, Variable Speed, Robust Construction

- Surface Finish

- Powder Coated / Polished Stainless Steel

- Power Consumption

- Depends on model (typically 5 40 kW)

Dissolver Motorized Lifting Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Dissolver Motorized Lifting

S. F. Engineering Works is the most profound and prominent manufacturer, exporter and supplier of Dissolver Motorized Lifting. We provide the wide range of motorized lifting and are well accredited in the market for its distinctive features like robust and sturdy construction, easy installation and longer working life. The machine is highly in demand in the market in several industries which are available in different technical specifications to meet our clients expectations. The Dissolver Motorized Lifting is available at a very cost effective price.

Further Details, Manufacturing and Supply:

HP: A high speed disperser is provided with 2 HP mechanically motorized lifting arrangement for mixing materials of specific gravity ranging from 1 to 1.3 Premix Capacity liters.

Body: The frame is made from angles and house the body casting and guide pipe. The base is 12 mm thick made from MS plates. The top frame has motor and shaft assembly.

Agitator: The shaft is 38 mm in diameter made of SS. MOC and is tapered to 33 mm diameter. The shaft is supported by two ball bearings. The bearings is housed in a MS. Housing is bolted to the top frame. The shaft has 6.5 (150 mm) Cowles type impeller blade for dispersion.

Drive: The shaft is powered by a 5 HP 1440 RPM, 3 phase squirrel cage induction and NON-FLP motor through V groove pulley and belts. The shaft speed is fixed 1440 RPM motor for screw type mechanical lifting arrangement of the stirrer.

Vessel: Vessel is fabricated from stainless steel SS 304 plates and is provided with three castor wheels. Bottom, the discharge ball valve and towing handles is made from SS 304.

Control Panel (Non Flame Proof/Flame Proof)

The control panel is duly powder coated and is provided with the followings functions:

- Main motor ON/OFF

- Voltmeter

- Ammeters

- Inverter Trip

- Emergency Stop

- Indicating lamp

- Speed Control Switch

- MCB

- RPM Indicator

Finish: All parts are stainless steel and are duly polished to a bright or matt finish. All MS parts are painted with two coats of metal primer and polyurethane paint. Machine is designed for the solvent based paints having viscosity of poise and sp gr. of 1.2. the water based paints having viscosity of 15 poise and sp gr. of 1.3.

Motorized Hydraulic Lifting for Enhanced Productivity

The DML Series dissolver utilizes a reliable motorized hydraulic lifting mechanism, allowing hassle-free raising and lowering of the mixing head. This feature contributes to improved operator safety and faster batch changes, making it suitable for continuous production environments.

Versatile Material Options for Diverse Industries

Manufactured in mild steel or stainless steel, the dissolver meets a broad spectrum of application needs, from paint and ink blending to pharmaceutical formulations. Clients can opt for the material finish and color that best suits their process and hygiene standards.

Digital Control and Variable Speed Operation

Equipped with a user-friendly digital control panel, the system offers precise speed adjustments and monitoring. Operators achieve consistent results and optimal efficiency for each batch, regardless of viscosity or volume.

FAQs of Dissolver Motorized Lifting:

Q: How is the Dissolver Motorized Lifting system operated for different applications?

A: The system is easily controlled via a digital control panel, allowing operators to adjust mixing speed and hydraulic lifting according to batch size, material viscosity, and desired process outcomes. This flexibility ensures optimal results across various usages, including paint, ink, and chemical blending.Q: What are the material options available for construction, and how does this benefit my process?

A: Clients can choose between mild steel or stainless steel construction, depending on their process requirements. Stainless steel provides superior corrosion resistance and hygiene, making it ideal for pharma and high-purity chemical production, while mild steel offers cost-effective durability for paints and coatings.Q: When should I consider customizing the dissolvers dimensions, power, or color?

A: Customization is recommended when your production space, batch requirements, or branding necessitate specific dimensions, power capacities, or color schemes. Customization ensures seamless integration into existing facilities and compliance with your operational preferences.Q: Where can the Dissolver Motorized Lifting be installed, and what industries benefit from its use?

A: This system is suitable for installation in manufacturing plants engaged in paints, adhesives, coatings, chemicals, pharmaceuticals, and emulsions. Its variable speed, robust construction, and easy-clean features make it beneficial for any facility needing high-capacity dissolving and mixing.Q: What is the process for cleaning and maintaining the DML Series dissolver?

A: The dissolver is designed for easy cleaning, featuring powder-coated or polished stainless-steel finishes and accessible components such as the impeller blade and lifting cylinder. Routine maintenance includes checking the hydraulic system, cleaning the impeller and mixing tank, and inspecting safety shields.Q: How does using a motorized hydraulic lifting system improve efficiency and safety?

A: Motorized hydraulic lifting enables smooth, controlled movement of the mixing head, reducing manual effort and the risk of accidents. It accelerates batch changes and cleaning processes, yielding higher throughput and safer workplace conditions.Q: What are the key benefits of using the DML Series for batch mixing operations?

A: The DML Series offers robust construction, customizable configurations, variable speed control, and efficient motorized hydraulic lifting, resulting in reliable high-capacity production, energy-efficient operation, easy maintenance, and adaptability across multiple industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Simultaneous Metering & Blending

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Speed : Variable; 10100 rpm

Drive Type : Electric

Driven Type : Motor

Weight (kg) : Approx 320 kg

Gravity Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Speed : Up to 60 bpm

Drive Type : Electric

Driven Type : Electric

Weight (kg) : Approx. 350 kg

Drum Decanting Units(DDU)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Speed : Variable

Drive Type : Other, Electric Motor

Driven Type : Motor driven

Weight (kg) : 1200 kg approx

Base Oil Transfer Pump

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Speed : 1450 rpm

Drive Type : Other, Electric Motor

Driven Type : Electric

Weight (kg) : Approx. 85150 kg (Varies by model)

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free