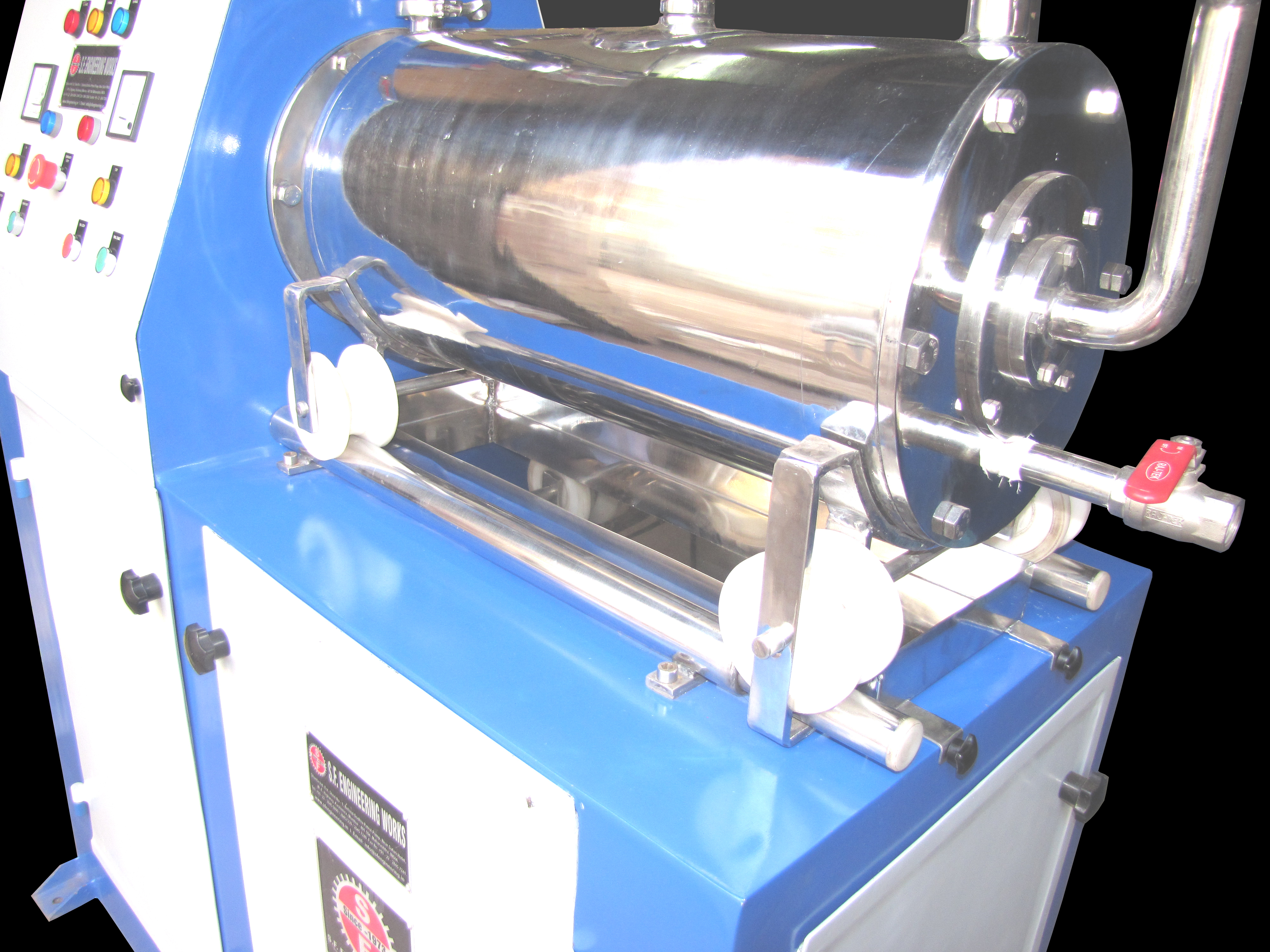

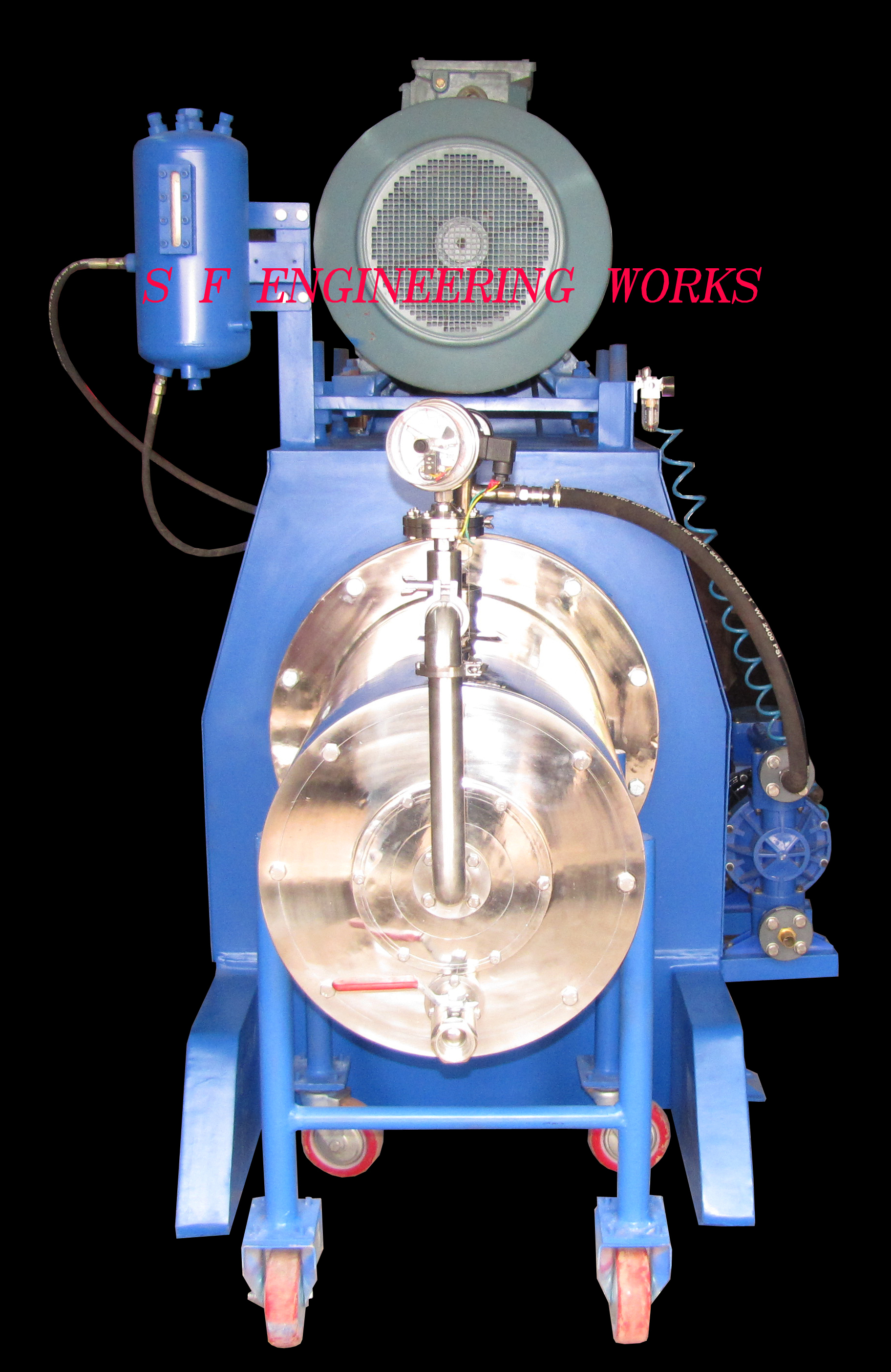

HORIZONTAL PRESSURIZED SAND MILL

Price 1 INR/ Unit

HORIZONTAL PRESSURIZED SAND MILL Specification

- Type

- Horizontal Pressurized Sand Mill

- Material

- Stainless Steel

- Capacity

- 5 to 100 Liters (varies by model)

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 220-415V AC

- Power

- 5-30 HP (depending on model)

- Weight (kg)

- 650-1200 kg

- Dimension (L*W*H)

- 1700 x 800 x 1500 mm (standard size, may vary)

- Color

- Blue & Silver (customizable)

HORIZONTAL PRESSURIZED SAND MILL Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About HORIZONTAL PRESSURIZED SAND MILL

APPLICATION:

ThisSeries Of Bead Mills Are Efficient Ultra Micro Wet Grinding And DispersingMachines In Common Use, And They Are Widely Used For Producing Coating,Dyestuff, Paint, Ink, Medicine, Magnetic Powder, Sensitive Film, Pesticide,Cosmetics And Paper Making, And So On. We Use Advantages Of The Same Kind OfMill In Our Country On These Mills. So These Mills Have High Efficiency, AndCan Work Continuously And Have Less Pollution, Its Self-Control Is Dependable.Its Cost Is Low. Its Appearance Is Nice. The Maintenance Is Convenient.Especially These Mills Are Very Practically Useful.

Precision Dispersion for Superior Products

Engineered to handle applications such as paint, ink, pigment, and coating dispersion, the Horizontal Pressurized Sand Mill delivers consistent, high-quality output. Its polished stainless steel construction and reliable PLC control make it ideal for demanding industrial environments.

Optimized Performance and Safety

With an automatic grade and advanced safety mechanisms-including emergency stop, overload detection, and auto shut-off-the sand mill guarantees a secure, user-friendly operating experience. The water-cooled jacketed housing ensures continuous, regulated temperature for reliable performance.

Customizable and User-Focused Design

Available in chamber sizes from 5 to 100 liters and offering customizable colors, the sand mill adapts to diverse production volumes and aesthetic preferences. Its electric drive supports operational efficiency, while included feeding pumps enable streamlined processing workflows.

FAQ's of HORIZONTAL PRESSURIZED SAND MILL:

Q: How does the horizontal pressurized sand mill maintain optimal process temperature?

A: The mill is equipped with a jacketed housing designed for water cooling, which efficiently dissipates heat generated during operation. This ensures consistent product quality and prevents overheating of materials during grinding and dispersion.Q: What materials can be processed using this sand mill?

A: This machine is suitable for dispersing and grinding a wide range of materials, including paint, ink, pigments, coatings, and dyes. Its versatility makes it valuable for various industries requiring precise particle size reduction and dispersion.Q: When is it beneficial to use a pressurized discharge method?

A: A pressurized or pneumatic discharge method is advantageous when processing high-viscosity products or when quick, clean product transfer is needed. It enhances throughput and reduces residue, especially in industrial-scale operations.Q: Where is this sand mill typically used?

A: The horizontal pressurized sand mill is commonly utilized in manufacturing facilities and processing plants, particularly within the paint, ink, pigment, and chemical industries. It is ideal for exporters, manufacturers, and suppliers seeking reliable dispersion solutions.Q: What safety features are included with the sand mill?

A: The machine includes multiple safety features, such as an emergency stop button, overload protection system, and automatic shut-off. These measures help protect operators and equipment, ensuring safe and consistent operation.Q: How does the PLC control system enhance milling operations?

A: The PLC (Programmable Logic Controller) system offers automated control over operating parameters, improving process accuracy and repeatability. This minimizes manual intervention, streamlines workflows, and reduces the likelihood of operator error.Q: What are the benefits of using stainless steel construction in this sand mill?

A: Stainless steel provides excellent resistance to corrosion and chemical attack, ensuring long-lasting performance and easy cleaning. The polished surface finish further enhances hygiene and reduces product contamination risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Paint Manufacturing Machines Category

Paint Manufacturing Machines

Price 600000.0 INR / Unit

Minimum Order Quantity : 1

Warranty : 1 Year

Type : Paint Manufacturing Machine

Computerized : No

Drive Type : Electric

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS