Showroom

We are manufacturing a wide range of Industrial Plants And Machinery. Among these products, our toilet soap finish line are more appreciated by our customers as they have the capacity ranging from 50 Kgs to 2000 Kgs per hour.

We supply our clients with foremost Grease Manufacturing Plants which have excellent performance without any hazard. These can process different types of grease like soda, lithium, calcium, aluminum, PTFE etc.

Our company's paint manufacturing machines are acquiring market with its salient features. The every part of these machines like horizontal sand mill, attritor, bead mill, disperser, putty mixer etc. works intensively.

We are known in the market for supplying remarkable Resin Manufacturing Plants. Due to its wide capacity range from 10 to 100 liters, these products satisfy every processing industry needs.

To meet the growing demand in the architecture, we come up with bitumen emulsion plant. These are widely used in the road construction as well as. With proper blending, these plants give hassle free service.

With the high speed stirrer, we ensure our customers with perfect blending process. These products are widely used in the chemical, pharmaceutical and food industry for blending various types of heterogeneous mixtures.

To make the work troublefree, we provide our clients with the Attritor Mill. These machinery are used for grinding, blinding and milling various liquids. With the innovative features, it completes its job fluently.

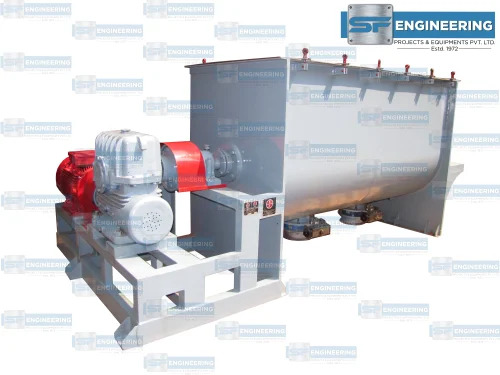

For mixing the homogenous dry powder, we serve clients with Ribbon Blender Powder Mixer. These products are widely used in the pharmaceutical, chemical, food processing industries etc. With the perfect blending, it make job hassle free.

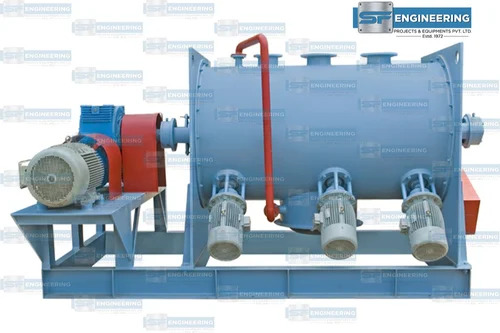

Sigma kneader extruder is meant to mix/knead and discharge heavy viscous material. The operator is not exposed to the material processed inside the machine.

Get in touch with us to buy this oil centrifuging machine meant for clarifying and other applications. This machine is driven by an electric motor.

Bead mills are generally used to reduce the particle size of ceramic, metal or glass beads. Fine particles can be reduced to sub-micron size. Customers can install bead mills with a low cost capital investment.

Dry mix mortar plant is a combination of different equipment which work in coordination to complete the task of making dry mix mortar. Dry mix mortar is basically produced by blending sand, cement, water and other raw material.

S. F. ENGINEERING WORKS

GST : 27ARUPS7370Q1ZE

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry Send SMS

Send SMS