Toothed Colloid Mill

Price 1.50000 INR/ Piece

Toothed Colloid Mill Specification

- Frequency

- 50/60 Hz

- Model No

- TCM-05

- Usage & Applications

- Food, Pharmaceutical, Chemical, Cosmetic Industries

- Installation Guideline

- Floor Mounted; Simple Installation

- Driven Type

- Motor Driven

- Accessories

- Standard Tools, Instruction Manual

- Speed

- 2800 RPM

- Efficiency (%)

- Up to 98%

- Temperature Range

- Ambient to 80C

- Motor Power

- 3 HP

- Automation Grade

- Automatic

- Production Capacity

- 300 to 500 L/hr

- Type

- Toothed Colloid Mill

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Manual

- Drive Type

- Electric Motor

- Voltage

- 220 - 440 V

- Power

- 3 HP

- Weight (kg)

- Approx. 120 kg

- Dimension (L*W*H)

- 600 x 300 x 700 mm

- Color

- Silver / White

- Capacity

- 50 to 500 L/hr

- Features

- High Shearing, Fine Grinding, Durable Body, Easy to Operate

- Machine Type

- Industrial Pulverizer/Colloid Mill

- Power Consumption

- 2.2 kW

- Surface Finish

- Polished

Toothed Colloid Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Toothed Colloid Mill

Holding a highly reputed and trusted market standing, we are engaged in manufacturing and supplying Toothed Cooloid Mill. It is mainly used for the wet milling of liquid to highly viscous products, if necessary with different milling sets. It is employed primarily in the chemical industry as well as in food production. This mill is suitable for the production and processing of juices, soy milk, hazelnuts or meat pastes. Toothed Cooloid Mill is built to offer high throughput performance within minimal space and optimal reproducibility. It has innovative grinding technology with perfect grinding chamber design.

Precision and Versatility in Fineness Control

The Toothed Colloid Mill allows exact fineness adjustments through rotor/stator gap control, enabling you to achieve specific particle sizes required in various industrial processes. This feature makes it an ideal choice for applications demanding uniform results, from pharmaceuticals to food emulsions, by simply adjusting the gap while in operation.

Designed for Safety, Hygiene, and Easy Cleaning

Engineered to meet stringent GMP and CE standards, this machine incorporates overload protection, a sealed drive, and CIP (Clean-In-Place) compatibility for effortless cleaning. Its stainless steel construction and polished finish ensure hygiene while minimizing maintenance downtime, supporting productivity and compliance.

Built for Performance and Durability

With a powerful 3 HP motor and grease-lubricated bearings, the mill offers high shearing force and reliable performance under atmospheric pressures. Its hardened stainless steel spindle and wear-resistant build guarantee longevity. Optional castor wheel mounting ensures mobility, making it convenient for varied industrial settings.

FAQs of Toothed Colloid Mill:

Q: How does the rotor/stator gap adjustment benefit the production process?

A: The rotor/stator gap adjustment allows precise control over the fineness of the processed material. This feature enables you to tailor the final particle size according to application needs, ensuring consistent product quality for different industrial processes.Q: What types of materials and industries is this colloid mill suitable for?

A: This machine is suitable for processing a variety of substances, including food, pharmaceuticals, chemicals, and cosmetic products. It effectively handles high-shear mixing, fine grinding, and homogenizing tasks across these diverse sectors.Q: When is the Clean-In-Place (CIP) system recommended for use?

A: The CIP system should be used after every production batch or when switching between different products, especially in industries like pharmaceuticals or cosmetics where cross-contamination must be avoided. This ensures thorough, efficient, and hygienic cleaning of internal components.Q: Where should the TCM-05 Colloid Mill be installed for optimal performance?

A: The machine is floor-mounted and designed for simple installation. It should be placed in a well-ventilated, dry area with access to electric supply (220440V) and adequate working space, following the installation guidelines provided in the instruction manual.Q: What are the key safety features of this colloid mill?

A: Key safety features include overload protection, mechanical sealing to prevent leakage, and a fully enclosed design. These attributes help safeguard users against operator error and equipment damage during intensive processing tasks.Q: How can the operator monitor and control the milling process?

A: Operators adjust process parameters manually via the control system. Essential adjustments include setting the rotor/stator gap for appropriate particle size and monitoring the machines operation, ensuring efficient grinding and safety without needing computerized interfaces.Q: What are the operational and maintenance advantages of this model?

A: Operationally, the mill offers low noise (<75 dB), high efficiency, and easy operation. Maintenance is simplified thanks to grease-lubricated bearings, a mechanical seal, and CIP compatibility, reducing downtime and ensuring stable, long-term performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Autolube System

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Machinery Lubrication, CNC Machines, Textile Machinery, Industrial Automation

Features : Low Maintenance, Precision Lubrication, Durable Design, Corrosion Resistant

Power Consumption : 180 W

Capacity : 3 Litre

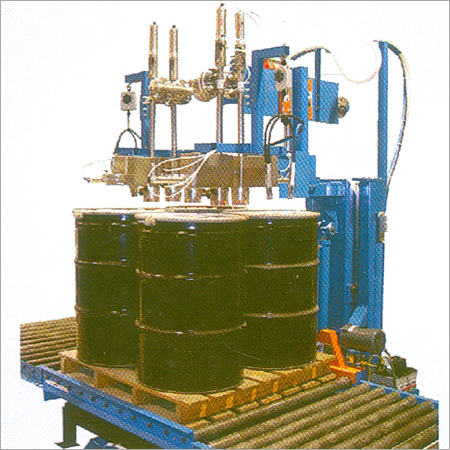

Drum Decanting Units(DDU)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Decanting viscous liquids from drums

Features : Efficient decanting, robust construction, easy maintenance, safety interlocks

Power Consumption : 2 kW/hr

Capacity : 200 L drum

Autoclave Pressurized Grease Kettle

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Grease manufacturing, Lubricant production, Highpressure blending

Features : High pressure resistance, Safe operation, Efficient heating, Durable design

Power Consumption : As per model typically 430 kW/hr

Capacity : 500 Litres 10,000 Litres

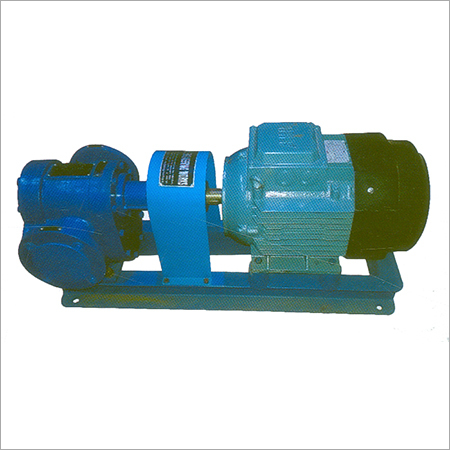

Feeding & Discharge Pump

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial fluid transfer, feed/discharge operations in process industries

Features : Corrosion Resistant, Robust Construction, Easy to Operate, Low Maintenance

Power Consumption : 2.2 kW

Capacity : Up to 600 LPH

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS