Dissolving Mixer Blender(DMB)

Price 1.50000 INR/ Piece

Dissolving Mixer Blender(DMB) Specification

- Model No

- DMB-500

- Efficiency (%)

- 98%

- Motor Power

- 3 HP

- Usage & Applications

- Pharmaceutical, Chemical, Food Processing, Cosmetic Industries

- Accessories

- SS Paddle, Scraper, PLC Panel (optional)

- Installation Guideline

- Floor Mounted, Easy Installation

- Speed

- 50-600 RPM (Adjustable)

- Driven Type

- Motor Driven

- Automation Grade

- Semi-Automatic

- Production Capacity

- 1000 kg/hr

- Frequency

- 50/60 Hz

- Temperature Range

- Ambient to 90C

- Type

- Dissolving Mixer Blender (DMB)

- Material

- Stainless Steel (SS304/SS316 optional)

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Electric Panel with Variable Speed

- Drive Type

- Gear Motor

- Voltage

- 220V/380V

- Power

- 3 kW

- Weight (kg)

- 450 kg

- Dimension (L*W*H)

- 1200mm x 800mm x 1600mm

- Color

- Metallic Silver

- Capacity

- 500 L

- Features

- High Shear Mixing, Homogeneous Blending, Low Maintenance

- Power Consumption

- 3.2 kW/hr

- Surface Finish

- Polished Stainless Steel

- Machine Type

- Industrial Mixer Blender

Dissolving Mixer Blender(DMB) Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Dissolving Mixer Blender(DMB)

Robust Construction and Versatile Design

Built from premium SS304 or optional SS316 stainless steel, the DMB-500 guarantees durability and corrosion resistance. Its design accommodates various industries by allowing customization of its impeller type, depending on your blending needs. The bottom discharge with a valve streamlines product removal, while the metallic silver polished finish enhances both hygiene and appearance.

Efficiency and Ease of Operation

With a powerful 3 HP gear motor and variable speed control, the DMB-500 achieves efficient mixing in just 1020 minutes per batch, supporting production rates up to 1000 kg/hr. The electric panel simplifies operation, while features like overload protection and emergency stop ensure user safety. The CIP-compatible design makes cleaning straightforward and time-saving.

Hygienic, Safe, and Low Maintenance

This mixer blender is cGMP compliant and features a gasketed lid to minimize contamination risks. Its noise level stays below 70 dB, maintaining a comfortable work environment. Designed for low maintenance, the DMB-500 supports continuous operation with a service life exceeding 10 years. Onsite & remote warranty support ensures your investment is well protected.

FAQs of Dissolving Mixer Blender(DMB):

Q: How does the Dissolving Mixer Blender ensure homogeneous blending for high-viscosity products?

A: The DMB-500 uses customizable impellers (flat blade, anchor, or paddle), high-shear mixing, and a robust gear motor to achieve uniform blending for products with viscosity up to 50,000 cps. This ensures consistency across pharmaceutical, chemical, food, and cosmetic formulations.Q: What safety features are incorporated into the DMB-500 for operator protection?

A: The mixer includes overload protection, an emergency stop button, and a gasketed lid to safeguard operators from accidental exposure or equipment failure during operation. These features comply with industrial safety standards, reducing risks in the workspace.Q: When and how should cleaning be performed on this equipment?

A: The DMB-500 is designed for easy cleaning, being fully CIP (Clean-in-Place) compatible. After each production cycle, operators can run the CIP protocol to sanitize internal surfaces without manual disassembly, significantly minimizing downtime between batches.Q: Where is installation suitable for the Dissolving Mixer Blender?

A: Thanks to its floor-mounted design and compatibility with forklifts, the DMB-500 can be effortlessly installed in various industrial environments, including manufacturing plants for pharmaceuticals, chemicals, food processing, or cosmetics.Q: What are the benefits of the bottom discharge valve on the DMB-500?

A: The bottom discharge with valve allows efficient and complete emptying of blended material, reducing wastage and simplifying batch transfer. This feature is particularly advantageous in applications demanding hygienic processing and quick product changeovers.Q: How does the variable speed control enhance the mixing process?

A: The electric panel enables precise adjustment of mixing speeds from 50 to 600 RPM. This flexibility allows operators to optimize mixing based on product properties, improving texture, preventing over-shearing, and ensuring high product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Automatic Batch Blender

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Motor Driven

Capacity : Up to 1000 kg/hr (model dependent)

Voltage : 380V415V

Automation Grade : Automatic

Conventional Blending Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric Motor

Capacity : 250 kg/batch

Voltage : 220240 V

Automation Grade : SemiAutomatic

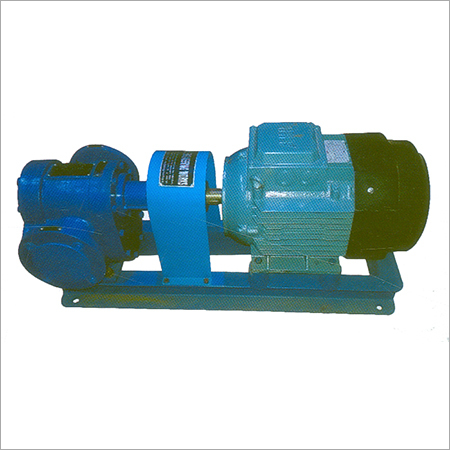

Feeding & Discharge Pump

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Capacity : Up to 600 LPH

Voltage : 220440 V

Automation Grade : SemiAutomatic

Autoclave Pressurized Grease Kettle

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric / Gear Motor Drive

Capacity : 500 Litres 10,000 Litres

Voltage : 415V / 380V / 220V (as per requirement)

Automation Grade : SemiAutomatic / Automatic

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS