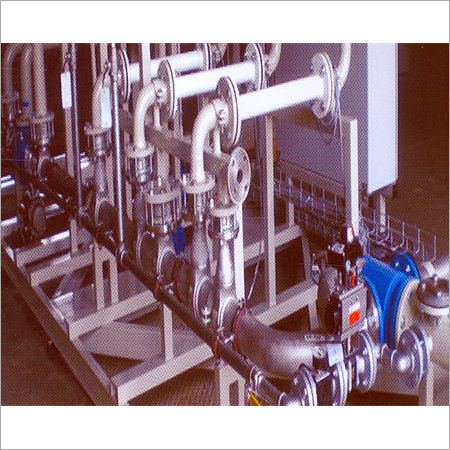

In-Line Blending System

Price 1.50000 INR/ Piece

In-Line Blending System Specification

- Usage & Applications

- Plastics Extrusion, Compounding, Masterbatch Production

- Production Capacity

- 1000 kg/hr

- Efficiency (%)

- 98%

- Motor Power

- 3 HP

- Driven Type

- Motor Driven

- Plastic Processed

- PE, PP, PVC, PS, ABS, Masterbatch

- Automation Grade

- Fully Automatic

- Temperature Range

- Up to 80C

- Installation Guideline

- Floor Mounted; Plug & Play

- Speed

- Variable 50 to 500 RPM

- Frequency

- 50/60 Hz

- Accessories

- Calibration Kit, Spare Parts Set

- Model No

- ILB-1000

- Type

- In-Line Blending System

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 220-240 V

- Power

- 3.5 kW

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 2200 x 950 x 1800 mm

- Color

- Grey

- Capacity

- Up to 6 components

- Features

- High Accuracy Metering, Real-Time Monitoring, Recipe Management, Modular Design

- Machine Type

- Continuous Blender

- Surface Finish

- Matt

- Power Consumption

- Low

In-Line Blending System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About In-Line Blending System

Enriched with immense market knowledge and expertise, we are engaged in manufacturing and supplying In-Line Blending System. It is a perfect dosing skid system to your specific product and ingredients. The system is built to blend both small, complex batches and large volume blends in a single system. The system optimizes operation by blending small batch blends with additive dosing and large volume, continuous blends, all in a single unit. It can maintain high accuracy dosing for a wide range of batch sizes. In-Line Blending System produces instantaneous finished product via the static mixer in the blend header combined with ratio control.

Unmatched Blending Precision

Achieve superior quality blends with up to 0.1% accuracy for consistent product results. The ILB-1000 supports blending up to 6 components, providing flexibility and precision for various plastics, including PE, PP, PVC, PS, and ABS. Its high efficiency and real-time digital monitoring ensure every batch is mixed to exact specifications.

Effortless Operation and Maintenance

The ILB-1000 is designed for ease of use, with fully automatic PLC controls and a plug & play installation. Maintenance is quick and tool-free, minimizing downtime. Operators benefit from low noise levels (<70 dB) and hygienic, matt-finish construction suitable for food and pharmaceutical processing.

Integrated Safety and Smart Connectivity

Safety is paramount with a built-in emergency stop and overload protection. Integration with existing SCADA/DCS systems enables seamless monitoring and control, supporting complex recipe management and production schedules. The modular design adapts to changing process needs with minimal effort.

FAQs of In-Line Blending System:

Q: How does the ILB-1000 ensure high blending accuracy in continuous processing?

A: The ILB-1000 utilizes precision metering technology and real-time monitoring to maintain blend accuracy within 0.1%. Its PLC-controlled operations and reliable dosing components ensure every batch is consistently mixed, regardless of fluctuations in flow or raw material properties.Q: What safety mechanisms are included with this in-line blending system?

A: This system is equipped with a dedicated emergency stop button and overload protection to safeguard personnel and equipment. These features help prevent accidents and ensure safe operation during both routine runs and maintenance activities.Q: When is batch processing available for the ILB-1000, and how does it benefit production?

A: Batch processing can be requested as an optional configuration. This is particularly useful for specialized or smaller production runs, offering flexibility and precise control over each batch without sacrificing blending accuracy or efficiency.Q: Where can the ILB-1000 be installed, and what industries is it most suitable for?

A: The system is floor-mounted and features a plug-and-play design, allowing for straightforward installation in various industrial settings. Its hygienic design makes it ideal for food, pharmaceutical, and plastics industries, especially where cleanliness and regulatory compliance are required.Q: What is the process for integrating the ILB-1000 with an existing SCADA or DCS control system?

A: Integration is streamlined due to the systems built-in compatibility with SCADA/DCS platforms. Complete documentation and support are provided to facilitate data communication, enabling central monitoring, recipe management, and automated system adjustments.Q: How does the ILB-1000 simplify maintenance and cleaning operations?

A: The system features low-maintenance, tool-free disassembly, enabling quick access for routine cleaning or part replacement. Its stainless steel, matt-finished surfaces resist residue build-up, supporting both hygiene and operational uptime.Q: What are the main benefits of using this in-line blending system in plastics and masterbatch production?

A: Key advantages include precise component dosing for quality consistency, automated operation for reduced manual labor, high throughput of up to 1000 kg/hr, and the flexibility to process a variety of polymers and masterbatches. The modular, energy-efficient design lowers operational costs while ensuring product safety and traceability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Semi Automatic Grease Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Accessories : Nozzle set, bottle support, power cable

Speed : Adjustable

Frequency : 50 Hz

Capacity : Up to 25 kg per batch

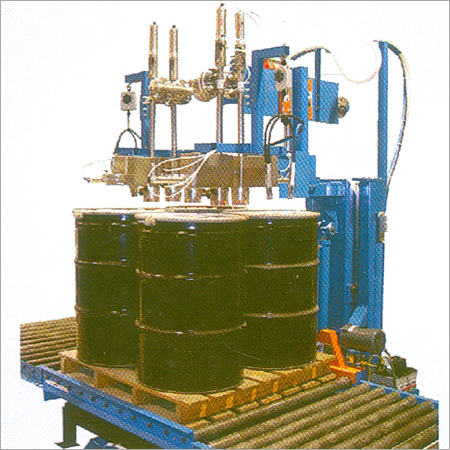

Drum Decanting Units(DDU)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories : Drum lifting arrangement, spill tray, hose pipe

Speed : Variable

Frequency : 50/60 Hz

Capacity : 200 L drum

Lube Oil Blending Plant

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories : Pumps, Flow meters, Control panels, Loading/Unloading arms, Storage tanks, Valves

Speed : Variable, up to 1800 rpm

Frequency : 50 Hz

Capacity : 500 L to 20,000 L per batch

Autolube System

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories : Oil Tank, Timer, Tubing, Pump

Speed : 1400 RPM

Frequency : 50 Hz

Capacity : 3 Litre

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS