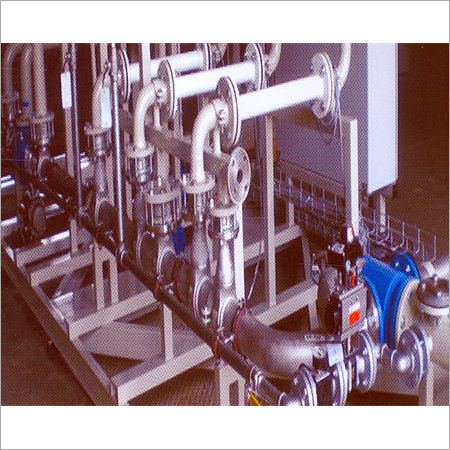

Lube Oil Blending Plant

Price 1.50000 INR/ Piece

Lube Oil Blending Plant Specification

- Automation Grade

- Automatic

- Installation Guideline

- Foundation & Utility Requirement as per Manuals

- Motor Power

- 7.5 15 HP

- Accessories

- Pumps, Flow meters, Control panels, Loading/Unloading arms, Storage tanks, Valves

- Temperature Range

- Room Temp to 120C

- Production Capacity

- 5,000 L to 60,000 L/Day

- Model No

- LOBP2024

- Usage & Applications

- Mixing, heating, and blending of base oils and additives for production of engine oils, hydraulic oils, gear oils, etc.

- Speed

- Variable, up to 1800 rpm

- Efficiency (%)

- Above 95%

- Frequency

- 50 Hz

- Driven Type

- Motor-driven mechanical agitator

- Type

- Lube Oil Blending Plant

- Material

- Mild Steel, Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- Electric

- Voltage

- 415 V, 3 Phase

- Power

- 15 kW

- Weight (kg)

- 1500 - 3000 kg (Depending on Capacity)

- Dimension (L*W*H)

- Customizable (Standard: 6000 x 3500 x 3800 mm)

- Color

- Industrial Grey / Blue (as per order)

- Capacity

- 500 L to 20,000 L per batch

- Features

- High blending accuracy, Compact design, Energy efficient, User friendly interface

- Machine Type

- Batch & Continuous Type

- Surface Finish

- Powder coated / Painted, Internal surfaces SS304

- Power Consumption

- 15 30 kW (Depending on Model)

Lube Oil Blending Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Lube Oil Blending Plant

Advanced Mixing Technology for Enhanced Productivity

Leveraging a multi-stage agitator with strategically placed baffles, the LOBP2024 ensures thorough and uniform blending of base oils and additives. Variable speed control (up to 1800 rpm) allows for flexible operation, adapting to specific blending needs while maintaining an efficiency of above 95%. The system can handle both batch and continuous processes, providing remarkable versatility in production.

Integrated Safety and Automation Controls

Safety and operational integrity are paramount, with features such as emergency shut-off, over-temperature protection, and pressure relief valves. The plant is PLC controlled, facilitating automatic monitoring and regulation of temperature, flow, and levels. Data logging enables complete batch traceability, ensuring compliance with quality standards and process transparency.

Energy Efficient and User-Friendly Design

With intelligent use of steam or electrical heating systems and robust insulation, LOBP2024 delivers optimal energy efficiency. The compact, skid-mounted layout suits various space requirements and makes installation straightforward. Cleaning is simplified through a CIP-ready design, and a user-friendly interface offers seamless operation by plant personnel.

FAQs of Lube Oil Blending Plant:

Q: How does the Lube Oil Blending Plant achieve high blending accuracy?

A: The plant employs a multi-stage agitator with baffles for effective mixing, variable speed up to 1800 rpm, and automatic PLC control to monitor process parameters. These features together ensure precise and uniform blending of oils and additives, maintaining product quality and consistency.Q: What types of heating systems are integrated into this plant?

A: The LOBP2024 supports both steam and electrical heating systems, selectable based on site utilities and production needs. Automatic temperature control provides accurate maintenance of process temperatures up to 120C.Q: When is the Clean-in-Place (CIP) system utilized?

A: The CIP system is used as part of routine cleaning and maintenance, particularly during product changeovers or at scheduled intervals. It enables thorough internal cleaning of the plant without manual disassembly, reducing downtime and ensuring contamination-free operations.Q: Where can this lube oil blending plant be installed?

A: The compact, skid-mounted design allows installation in a wide range of industrial environments. It is suitable for both greenfield projects and upgrades in existing blending facilities. Customizable dimensions facilitate integration into varied plant layouts.Q: What is the process flow for producing blended lubricants in this plant?

A: Raw materials are loaded into the blending vessel, heated using the integrated system (steam or electric), mixed thoroughly by the multi-stage agitator, and all critical parameters (temperature, flow, and levels) are automatically controlled. The finished batch is then transferred to unloading or storage tanks, with full batch data logged for traceability.Q: How does batch traceability benefit users of this blending plant?

A: Integrated data logging tracks every batch, recording key parameters and process steps. This enhances quality assurance, eases regulatory compliance, and affords a transparent history of production, facilitating audits and customer confidence.Q: What utilities are required to operate this blending plant efficiently?

A: Operational requirements include electricity (415V, 3 Phase), steam or hot water for heating, and compressed air for instrumentation and controls. Detailed foundation and utility guidelines are provided in the installation manual for seamless commissioning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Gravity Filling Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1800 x 900 x 1500 mm

Color : Silver

Driven Type : Electric

Frequency : 50/60 Hz

Conventional Blending Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1450 x 1050 x 1350 mm

Color : Silver / Metallic

Driven Type : Electric Motor

Frequency : 50/60 Hz

In-Line Blending System

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 2200 x 950 x 1800 mm

Color : Grey

Driven Type : Motor Driven

Frequency : 50/60 Hz

Dissolving Mixer Blender(DMB)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1200mm x 800mm x 1600mm

Color : Metallic Silver

Driven Type : Motor Driven

Frequency : 50/60 Hz

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS