Gravity Filling Machine

Price 1.50000 INR/ Piece

Gravity Filling Machine Specification

- Usage & Applications

- Beverage, Edible Oil, Dairy, Chemicals, Pharmaceuticals, Cosmetics

- Speed

- Up to 60 bpm

- Automation Grade

- Automatic

- Temperature Range

- Ambient

- Accessories

- Standard change parts, Filling heads, Nozzle set

- Driven Type

- Electric

- Installation Guideline

- Onsite installation service available

- Model No

- GF-3750

- Motor Power

- 1.5 HP

- Efficiency (%)

- 98%

- Frequency

- 50/60 Hz

- Production Capacity

- 20-60 bottles/min

- Plastic Processed

- PET, HDPE, PP bottles

- Type

- Gravity Filling Machine

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220-240 V

- Power

- 1-3 kW

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 1800 x 900 x 1500 mm

- Color

- Silver

- Capacity

- 500 ml to 5 Liter (adjustable)

- Features

- Corrosion Resistant, Precise Filling, Easy Operation, Low Maintenance

- Surface Finish

- Polished

- Power Consumption

- 3 kW

- Machine Type

- Liquid Filling Machine

Gravity Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Gravity Filling Machine

We are a leading company specializing in the business of manufacturing and supplying Gravity Filling Machine. It is the most simplest and efficient filling system for non carbonated liquid. This machine comes with options of with and without partial vacuum depending upon applications. The filling mouth is provided with a leakproof device, ensure no leakage, no filling drawing. It is equipped with automatic mixing function, which makes the filling process more evenly mixed. Our Gravity Filling Machine is completely automated, inline packaging system and can be integrated into almost any existing packaging line. It is ideal to fill-liquor, pharma liquids, household liquids in glass rigid bottles and containers.

Precision and Flexibility for Bottled Liquids

Engineered for diverse bottled liquids, the GF-3750 offers highly customizable filling heads to accommodate varying production demands. Its precise filling capability, adjustable volume settings, and compatibility with a wide range of bottle types and sizes make it ideal for manufacturers seeking adaptable, automated solutions.

Reliable Hygiene and Safety

Constructed from 304/316 stainless steel with a polished finish, all product-contact parts ensure compliance with hygiene standards for food, beverages, and pharmaceuticals. Features such as emergency stop, overload protection, and full safety guards guarantee operator and product safety throughout operation.

Efficient Operation and Maintenance

GF-3750 supports low-maintenance, high-efficiency workflows. The Clean-in-Place (CIP) compatible design simplifies cleaning, while automatic or manual lubrication options and tool-less changeover help reduce downtime. The intuitive touchscreen HMI improves operator control over production settings and machine status.

FAQs of Gravity Filling Machine:

Q: How does the GF-3750 Gravity Filling Machine ensure precise liquid filling?

A: The GF-3750 achieves 1% filling accuracy through its PLC-controlled system and drip-proof, anti-leakage nozzles, providing consistent and reliable volumetric control for all types of bottled liquids.Q: What bottle types and materials can be used with this filling machine?

A: This machine supports round, square, and flat bottles made from materials such as PET, HDPE, and PP, within the diameter range of 40mm to 110mm.Q: What is the cleaning process for the GF-3750?

A: The GF-3750 is compatible with Clean In Place (CIP) systems, allowing for efficient internal cleaning without disassembly, which is essential for maintaining hygiene, especially in food and pharmaceutical applications.Q: Where can the GF-3750 Gravity Filling Machine be installed, and is onsite guidance available?

A: The machine is designed for installation at manufacturing sites with onsite installation support available. Standard change parts and accessories are supplied for seamless setup and operation.Q: What safety features are included with this filling machine?

A: Key safety features include emergency stop, overload protection, robust safety guards, and automatic shutoff, ensuring operator welfare and production integrity throughout its operation.Q: How does tool-less changeover benefit production efficiency?

A: Tool-less changeover significantly reduces downtime, enabling operators to switch between products or bottle sizes rapidly, thus maximizing output and minimizing operational interruptions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Conventional Blending Machine

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Usage & Applications : Plastic Compounding, Additives Blending, Masterbatch Mixing

Automation Grade : SemiAutomatic

Surface Finish : Polished

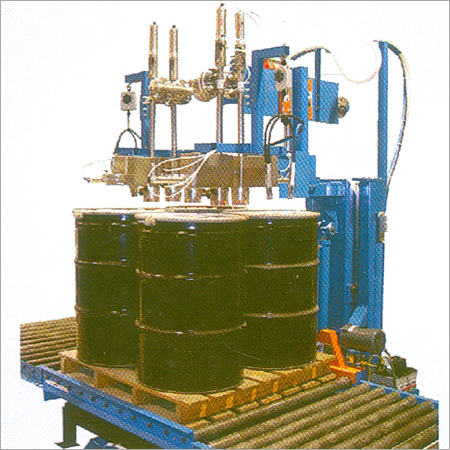

Drum Decanting Units(DDU)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Usage & Applications : Decanting viscous liquids from drums

Automation Grade : SemiAutomatic

Surface Finish : Polished

Vacuum Deaerator

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Usage & Applications : Liquid deaeration, Food & beverage, Pharmaceutical industry

Automation Grade : SemiAutomatic

Surface Finish : Polished

Lube Filling Line

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Usage & Applications : Used for filling lube oil, grease, and other viscous liquids into bottles or containers

Automation Grade : Fully Automatic

Surface Finish : Polished

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS