Chemical Dissolver

Chemical Dissolver Specification

- Speed

- 1400 RPM

- Temperature Range

- Ambient to 80C

- Driven Type

- Motor Driven

- Installation Guideline

- Floor Mounted, With Foundation Bolts

- Usage & Applications

- Dissolving Chemicals, Mixing Liquids, Paints, Coatings, Adhesives

- Frequency

- 50/60 Hz

- Efficiency (%)

- 97%

- Production Capacity

- As Per Requirement

- Source

- Manufacturer

- Automation Grade

- Automatic

- Motor Power

- 3.5 kW

- Accessories

- VFD Panel, Mixing Impeller, Safety Guard

- Type

- Chemical Dissolver

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric Motor

- Power

- 3.5 kW

- Weight (kg)

- 350 kg

- Dimension (L*W*H)

- 1750 mm x 850 mm x 1550 mm

- Color

- Blue

- Capacity

- 500 Liters

- Machine Type

- Industrial Mixer/Dissolver

- Power Consumption

- 3.5 Units/hr

- Surface Finish

- Polished

Chemical Dissolver Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

About Chemical Dissolver

At S. F. Engineering Works we have a team of skilled professionals and highly qualified engineers, we are considered as one of the most eminent manufacturer and supplier of Chemical Dissolver. These machines are available in different technical specifications to suit the diverse needs of our valued customers. The machines offered by us are available at a very competitive price range in the market. It is widely in demand in chemical industry for its salient features like easy installation, rugged design and less power consumption. The dissolver is available with A C drive 10HP to 75 HP.

Construction

Drive Head: A steel fabricated enclosure is inside which is installed with the drive assembly consisting of a set of balanced pulleys, electric motor, V belts and motor tensioning device. The drive head is hinged type construction which can be opened and locked for maintenance.

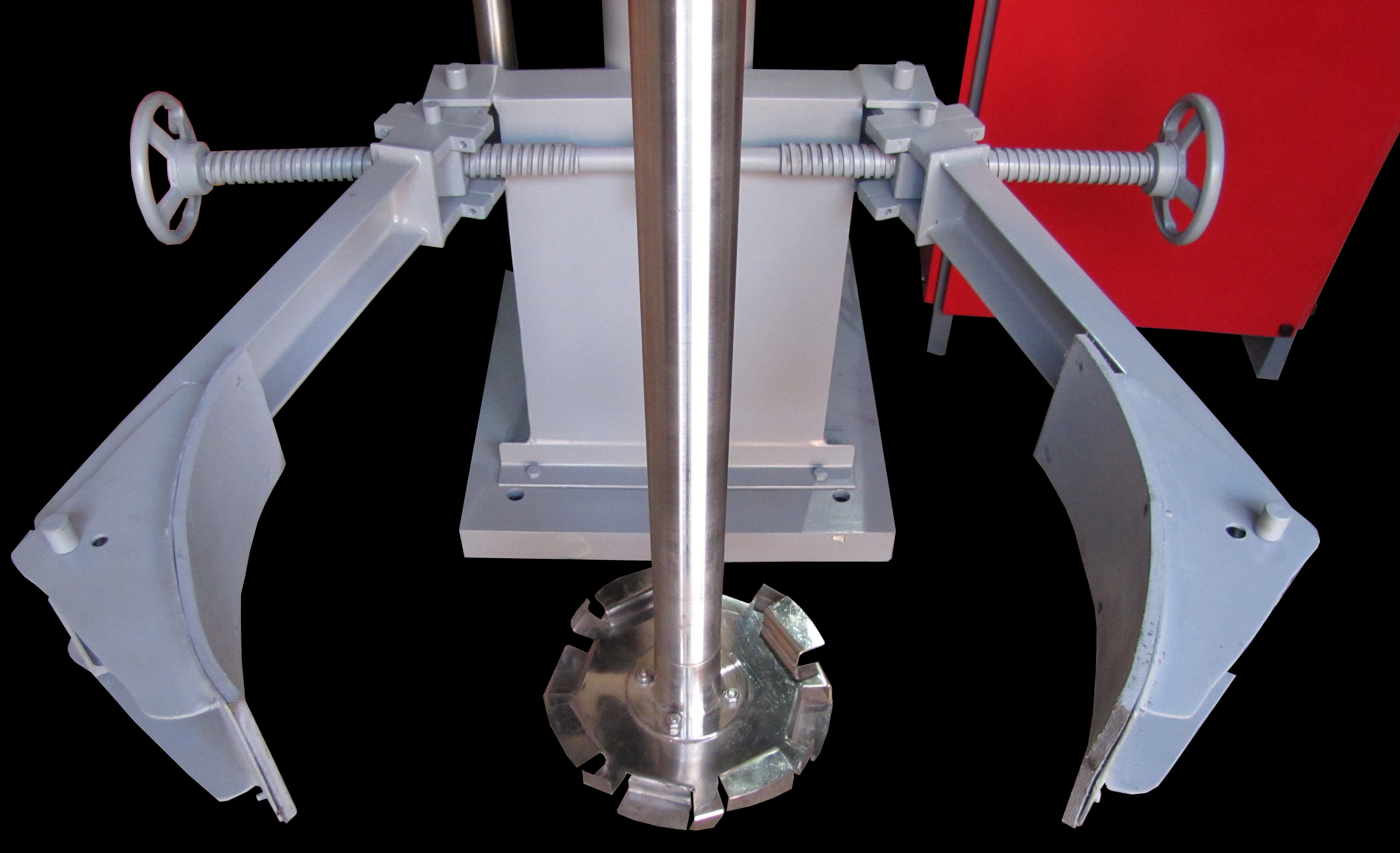

Main Shaft: A stainless steel SS 304 shaft which is duly machined and balanced is provided with a hard chrome plate, Cowles disperser blade which is specially designed for efficient and quick dispersion. Disperser blades made from special steel which can withstand high wear and tear. The shaft is installed in a bearing housing and is provided with taper roller bearings. RPM variable from 0 to 1500, the lubrication points are provided on the housing.

Speed Control: AC frequency inverter is installed in a panel controls with the RPM of the disperser shaft range from 0-1500. The inverter is provided with settings for monitoring torque, amperage, voltage, power factor and is PC compatible.

Electric Motor: 3 phases, 415 V, 50 HZ TEFC motor, drives a set of pulleys and V belts. The electric motor is provided with a belt tensioning device.

Lifting/Lowering: The entire drive head and shaft are mounted on a hydraulic column which makes it easier to lift and lower it to clear the height of the vessel. The hydraulic column comes complete with hydraulic cylinder, power pack unit, piston rod, valves 1HP electric motor and interconnecting pipelines and hoses.

Vessel locking: A vessel locking device consists of centering device, locking arms, and manually operated screw is provided.

Vessel Optional: The vessel is fabricated from SS 304 plates and is provided with 3 numbers castor wheels, SS 304 bottom discharge ball valve and towing handles.

Control Panel: A control panel which is duly powder coated is provided with the followings functions, Ammeters, voltmeter, main motor ON/OFF, emergency stop, indicating lamps, inverter trip, speed control switch, RPM indicator and MCB.

Finish: All Stainless steel parts are duly polished to a bright or matt finish. All the MS parts are painted with two coats of metal primer and polyurethane paint.

Advanced Automation for Seamless Mixing

This Chemical Dissolver utilizes a PLC-based control system for fully automatic operation. The integration of a VFD panel enables precise speed adjustments, leading to consistent product quality and enhanced safety standards. Automation minimizes manual intervention and streamlines industrial mixing processes.

Robust Design for Industrial Demands

Built from polished stainless steel, the dissolver withstands demanding environments and frequent chemical exposure. Its sturdy foundation bolts and floor-mounted installation guarantee operational stability, while accessories like impellers and safety guards increase both efficiency and user protection.

FAQs of Chemical Dissolver:

Q: How is the Chemical Dissolver installed, and what are its foundation requirements?

A: The dissolver is floor-mounted and should be fixed using the provided foundation bolts to ensure stability during operation. Installation must be performed on a level surface that can support the units weight of 350 kg, following the manufacturers guidelines for optimal performance and safety.Q: What types of chemicals and materials can this dissolver mix and process?

A: This industrial mixer is suitable for dissolving chemicals, mixing various liquids, and processing paints, coatings, and adhesives. Its high-efficiency motor and robust mixing impeller make it ideal for a wide spectrum of blending applications in manufacturing settings.Q: When should the variable frequency drive (VFD) panel be utilized during operation?

A: Use the VFD panel when adjustments to mixing speed are required, such as accommodating different viscosities or optimizing energy consumption for specific recipes. This feature allows precise control, ensuring ingredients are blended as per process requirements.Q: Where is the Chemical Dissolver commonly used in industrial environments?

A: The dissolver is primarily employed in chemical processing plants, paint and adhesive manufacturing facilities, and industrial coating operations. Its versatility makes it beneficial wherever large-scale liquid mixing or chemical dissolution is essential.Q: What is the typical process flow for operating the Chemical Dissolver?

A: Start by securely mounting the unit, then load the materials into the mixing chamber. Operate the control system via PLC, adjust the speed as necessary using the VFD panel, and monitor the process through the safety guard. Upon completion, stop the motor and safely unload the final product.Q: What are the main benefits of using this automatic, PLC-controlled dissolver?

A: Key advantages include reliable automatic operation, high mixing efficiency (97%), reduced labor due to automation, safety features for operator protection, and flexibility in processing varied chemical mixtures. The stainless steel build ensures long-term durability and minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Plant & Machinery Category

Toothed Colloid Mill

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Usage & Applications : Food, Pharmaceutical, Chemical, Cosmetic Industries

Drive Type : Other, Electric Motor

Dimension (L*W*H) : 600 x 300 x 700 mm

Lube Oil Blending Plant

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz

Usage & Applications : Mixing, heating, and blending of base oils and additives for production of engine oils, hydraulic oils, gear oils, etc.

Drive Type : Electric

Dimension (L*W*H) : Customizable (Standard: 6000 x 3500 x 3800 mm)

Dissolving Mixer Blender(DMB)

Price 1.50000 INR / Piece

Minimum Order Quantity : 1 Piece

Frequency : 50/60 Hz

Usage & Applications : Pharmaceutical, Chemical, Food Processing, Cosmetic Industries

Drive Type : Other, Gear Motor

Dimension (L*W*H) : 1200mm x 800mm x 1600mm

Autospheric Type Grease Kettles

Minimum Order Quantity : 1 Piece

Frequency : 50 Hz / 60 Hz

Usage & Applications : Preparation and processing of various grades of greases in lubricants industry

Drive Type : Other, Electric Motor Driven

Dimension (L*W*H) : As per model (Customizable)

GST : 27ARUPS7370Q1ZE

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS